I've bought the C8051F34X Development Kit (which is available at Digikey for small money) because I want to play a bit with USB devices and testing the 8051 instruction set and architecture. The Blinky sample worked without problems with the IDE. Compiling larger programs is difficult, because the Keil compiler is an evaluation version, only, which limits the maximum program size. But there is SDCC support in the IDE. I tried it, but couldn't figure out how to define aliases for registers, so I installed a later version of the ASxxxx assembler, which was used by SDCC. This version doesn't work with the IDE, because the command line arguments are different and the required output file name and format is different (looks like the Silabs IDE can't use Intel Hex for the toolchain generated files). The editor in the IDE is not very good anyway, so I switched to my favorite editor Ultraedit and used a small build.cmd script for compiling the file:

C:\Programme\ASXV4PXX\ASXMAK\VC6\EXE\AS8051.EXE -slox blinky.asm C:\Programme\ASXV4PXX\ASXMAK\VC6\EXE\ASLINK.EXE -i blinky blinky xcopy /y C:\SiLabs\MCU\Examples\C8051F34x\Blinky\blinky.ihx "c:\Dokumente und Einstellungen\Frank\blinky.hex"

The IDE has a nice option "Download object file" in the Debug menu, where you can specify an Intel Hex file, which will be flashed to the device. This setup works, so finally I have mastered the usual development tool quirks.

The demo program samples the ADC, which is connected to the pin on the development board with a potentiometer. It sends the average of 16 values, sampled every millisecond, every 16 ms, with the P2.0 state (a button on the devboard) in bit 7. Received bytes from the serial port are written to P2 (only for P2.2 and P2.3, the other bits are overwritten with 1 to avoid problems with the open drain GPIOs). This is the source:

.include "c8051f340.inc"

GREEN_LED1 == P2.2 ; green LED1

GREEN_LED2 == P2.3 ; green LED2

.define TEMP "R2" ; temporary register

.define ADC_COUNT "R3" ; current number of accumulated ADC samples

.define ADC_SUM_L "R4" ; accumulated samples value, low byte

.define ADC_SUM_H "R5" ; accumulated samples value, high byte

.area CODE (ABS)

.org 0

reset: ljmp start ; reset vector

.org 0x02B ; interrupt vector for timer2

ajmp timer2

.org 0x100

start: anl PCA0MD, #0xff-0x40 ; clear watchdog enable bit

mov OSCICN, #0x83 ; set oscillator to full speed internal clock, 12 MHz

; setup 4x clock multiplier

mov CLKMUL, #0x00

mov CLKMUL, #0x80 ; enable clock multiplier

clr a ; wait a bit for initialization

djnz acc, .

orl CLKMUL, #0xc0 ; initialize clock multiplier

cinit: mov a, CLKMUL

jnb ACC.5, cinit ; wait for stabilization

mov CLKSEL, #3 ; select full 48 MHz for system clock and USB clock

; setup ports

orl P2MDOUT, #0x0c ; make LEDs pin output push-pull

orl P2MDIN, #0x0c ; make LEDs pin input mode digital

setb GREEN_LED1 ; turn on LED1

anl P1MDIN, #0xff-0x02 ; set P1.1 as an analog input

; setup ADC

mov ADC0CN, #0x00 ; ADC0 disabled, normal tracking

mov REF0CN, #0x08 ; use VDD as AD reference

mov AMX0P, #0x04 ; ADC0 positive input = P2.5

mov AMX0N, #0x1F ; ADC0 negative input = GND (single ended mode)

mov ADC0CF, #0xfc ; set SAR clock to minimum and left-justify results

setb AD0EN ; enable ADC0

mov ADC_COUNT, #0x10 ; initialize counter for ADC accumulation

; setup timer2 for an interrupt every millisecond

mov TMR2CN, #0x00 ; stop timer2; clear TF2; use SYSCLK/12 as timebase for T2XCLK

mov TMR2RLH, #0xf0 ; init reload values

mov TMR2RLL, #0x60

mov TMR2H, #0xff ; set to reload immediately

mov TMR2L, #0xff

setb ET2 ; enable timer2 interrupts

setb TR2 ; start timer2

; setup UART0

orl P0MDOUT, #0x10 ; enable UTX as push-pull output

mov XBR0, #0x01 ; enable UART on P0.4(TX) and P0.5(RX)

mov SCON0, #0x10 ; 8 bit, ignore stop bit, rx enabled, 9th bits are zeros, clear RI0 and TI0 bits

mov TH1, #0x30

mov TL1, #0x30

orl CKCON, #8 ; T1M = 1 (timer1 UART baud rate generator uses system clock)

mov TMOD, #0x20 ; timer 1 in 8-bit autoreload

setb TR1 ; start timer1

setb TI0 ; Indicate TX0 ready

mov XBR1, #0x40 ; enable Crossbar

setb EA ; enable global interrupts

ajmp . ; wait forever

; timer2 interrupt handler

timer2: clr TF2H ; clear timer2 interrupt flag

lcall sample

dec ADC_COUNT

mov a, ADC_COUNT

jnz testA ; skip ADC output, until 16 values accumulated

mov ADC_COUNT, #0x10 ; reinitialize counter for ADC accumulation

lcall avg ; get average ADC value in accu

anl a, #0xfe ; discard lsb

rr a

jb P2.0, notSet ; test button

orl a, #0x80 ; set msb, if button is pressed

notSet: lcall emit ; transfer to RS232

testA: lcall avail ; test if RS232 data is available

jnb ACC.0, iend

mov a, SBUF0 ; get byte

orl a, #0xf3 ; set 1 for all input pins

mov P2, a ; save in port2

iend: reti ; return from interrupt

; sends a byte to RS232 and waits until transfered

emit: mov SBUF0, a ; send byte

emit2: mov a, SCON0

jnb ACC.1, emit2 ; wait until transfered

clr SCON0+1 ; clear transmit bit

ret

; tests, if a byte is available from RS232

; return: accu=1, if available, 0 otherwise

avail: mov a, SCON0

anl a, #1

clr SCON0+0

ret

; sample one ADC value and accumulate it in r5/r6

sample: setb AD0BUSY ; start AD conversion

waitAD: mov a, AD0BUSY ; wait until AD conversion is finished

jb ACC.0, waitAD

mov a, ADC0H

add a, ADC_SUM_L

mov ADC_SUM_L, a

jnc s2

inc ADC_SUM_H

s2: ret

; get the average of 16 accumulated ADC values from ADC_SUM and reinitialize it

; return: accu=average

avg: mov TEMP, #4

shift: clr C ; clear carry

mov a, ADC_SUM_H ; shift ADC_COUNT_L/ADC_COUNT_H one bit right

rrc a

mov ADC_SUM_H, a

mov a, ADC_SUM_L

rrc a

mov ADC_SUM_L, a

djnz TEMP, shift ; shift four times = divide by 16

mov a, ADC_SUM_L ; return result in accu

mov ADC_SUM_L, #0 ; reinitialize ADC_SUM

mov ADC_SUM_H, #0

ret

I like the instruction set, the bit-set and bit-clear operations are very handy. And many instructions of the C8051F34X chips are executed in one ow two clock cycles, which means you have up to 48 MIPS speed (but with some Silabs parts the system clock is limited to 25 MIPS). No external clock is required, the internal 12 MHz clock can be divided and multiplied up to 48 MHz, if the accuracy from 11.82 MHz to 12.18 MHz is sufficient.

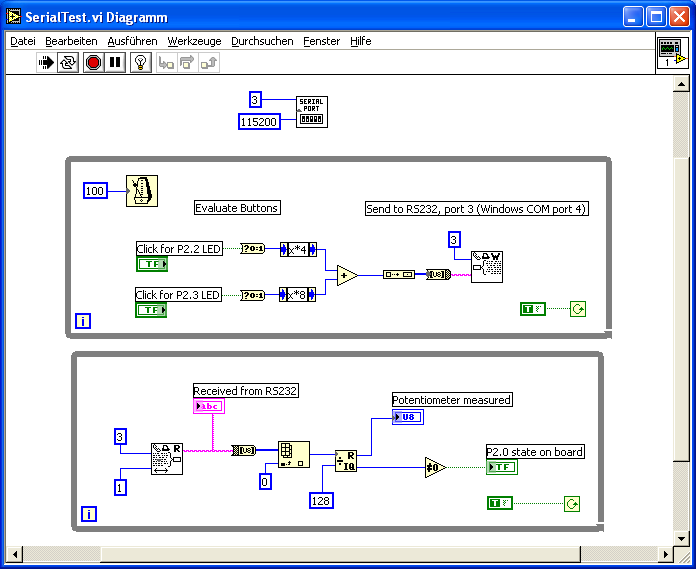

Some time ago there was a full version of LabView in a German computer magazin DVD for personal use. I've seen some expensive PCI cards for integration with LabView, with ADC, GPIOs etc., but for many tasks the multiplexed ADCs and many GPIOs of one Silabs chip, wired with RS232 to the PC, is all you need to control and measure some external hardware, so this was a good test for me to try out LabView, because the graphical, schematic-like programming environment looks very user friendly and easier for electronic engineers than writing some text programs. And after reading some tutorials, finally I managed to create my first Virtual Instrument. Once you have learned the basics, it is very easy to create your own instruments. To do all the minor format conversions, numerical constants etc. with symbols needs getting used to, but the same is true for writing programs with a text editor. I don't know how it scales for bigger projects (but you can encapsulate functionalities inside user defined symbols, which should help), but this small project looks very nice and clear, and it is fun to work with.

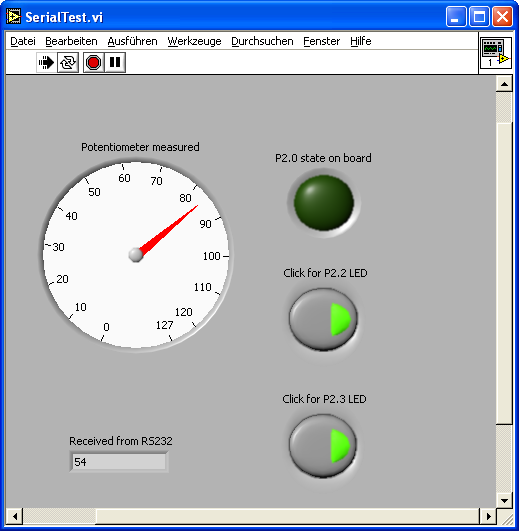

This is the GUI of the virtual instrument:

The pointer of the round instrument is updated very fast when tuning the potentiometer and there is nearly no CPU usage.

The flow diagram for this instrument:

You can download the instrument. Maybe I'll buy the commercial version and use it more often instead of writing text programs. For virtual instruments it is more natural to just draw it instead of writing lots of text for implementing it.